In recent years, IR-vacuum drying has been examined as a potential technique for obtaining high quality dried various agricultural products, including fruits, vegetables, and grains.

IR-vacuum drying combines the advantages of both IR heating and vacuum drying. The low temperature and rapid mass transfer conferred by vacuum combined with high energy transfer by IR heating generates very rapid, low temperature drying and thus it has the potential to develop energy efficiency and quality of products.

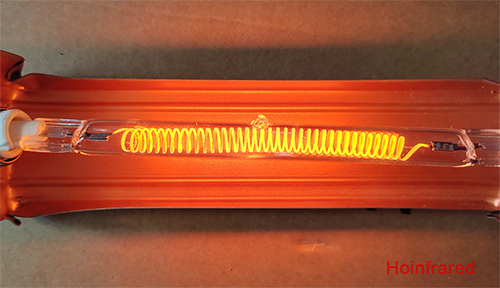

Using IR heating to food drying is newly of special interest due to the development in radiator construction. IR heating effectiveness is between 80% and 90%, the emitted radiation is in narrow wavelength range and they are miniaturized.IR heating has many benefits including uniform heating, low processing time, high heat transfer rate and energy consumption, and improved product quality.

In addition, IR drying found also application in various food analyses to measure water content in food products . Advantages of IR radiation over convective heating include high heat transfer coefficients, short process times, and low energy costs.

Comparison of IR drying with convective drying of apple showed that drying time of the process can be shortened to about 50% when heating is done with IR energy. Specific energy consumption was lower, and thermal efficiency was higher for the IR-hot air setting when compared to both IR and hot air settings.

These tubular halogen lamps offer numerous important benefits.on the normal electric mains supply.And they are highly energy-efficient:because they convert virt......