Scan the QR code

Advantages

1. Best Directional heating radiation.

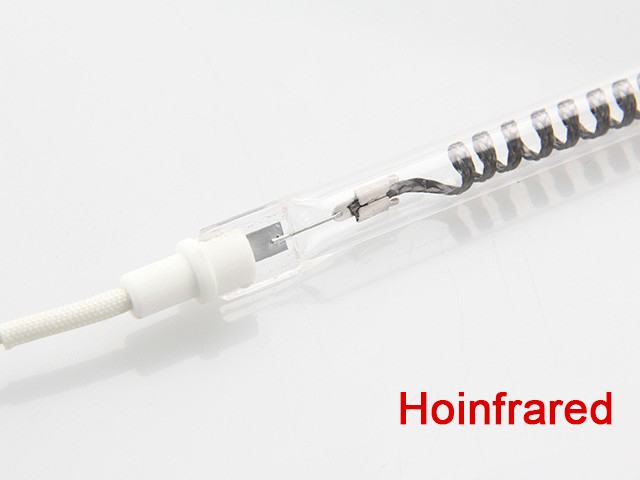

2. Fast response 1-2 seconds response time.

3. Good quality quartz tube with superior thermal stability

4. Excellent heating efficiency.

5. Ceramic end cap.

6. We can customize them for you, from 200w-6000w / 120v-480v.

When using infrared heater with reflectors, The heating process are running more steady and more efficiently. The Reflectors Provide directional IR radiation. The reflective coating consists of a high-purity quartz, ceramic material and some of fine gold, which is coated on the surface of The quartz tubes. therefore, the emitter has better performance in small working space. The quartz heaters is good resistant to heat, acid and corrode. As a result, The emitter with this refelctive coating can be used many extrem conditions.

The carbon infrared heater has a heating length starting from 50mm to 3000mm and is suitable for being a separate heating process. These new emitters are particularly suitable for curing small parts, drying painting, plastics welding, or for The areas where local heating is required. According to the customer's requirement, we can customize the carbon infrared heater as twin tube or single tube with gold reflective coating .

The carbon infrared heater can be used in Horizontal and vertical, with Energy-saving heating process and Fast response time. wavelength: up to 2.2 μm.

A wide range of applications

Printing industry: glue and ink drying, curing;

Glass industry: glass annealing and drying;

Shoe industry: glue activation dry;

Furniture industry: fast drying;

Rubber industry: plastic softening, molding and cable production;

Photovoltaic industry: sintering, substrate drying, spray preheating;

Automotive Industry: Complete Car Painting Drying and Local Paint Repair;

Textile industry: fabric preheating, drying, pressing and adhesive activation;

1. Components are allowed to work under the following conditions:

A. The relative humidity of the air is not more than 95 percent.

B. There is no flammable, explosive, corrosive gas and conductive dust in the surrounding environment.

C. Without violent impact and vibration;

D. The working voltage should not be greater than 1.1 times the rated value, and it can also be effectively grounded.

E. Insulation resistance ≥ 1MΩ Dielectric strength: 2KV/1min.

2. The electric heating pipe should be well positioned and fixed. The electric heating pipe is generally equipped with corresponding metal pipe clamps and ceramic pipe clamps according to the porcelain seats at both ends.

When the operating temperature exceeds 200 degrees Celsius, a high-temperature wire and screw connection that withstands 400 degrees or more is used.

3.Insulating material of infrared electric heating tube The quartz glass is a brittle material. When installing and using it, it should be safe and use it according to the specific conditions of the heated object.

Take necessary protective measures to avoid mechanical damage