In modern industrial and scientific research fields, the demand for high-temperature material processing is increasing day by day. Traditional heating methods are difficult to meet the dual requirements of high efficiency and high precision, especially in the high-temperature range above 1200℃. However, with the development of infrared focusing heating technology, this problem is beginning to be solved. Infrared focusing heaters, with their unique advantages, are revolutionizing our understanding and application of material processing at high temperatures.

Infrared dot-focused heater is a light soldering system designed for integration into automatic production systems. It consists of a light source, control and power unit.

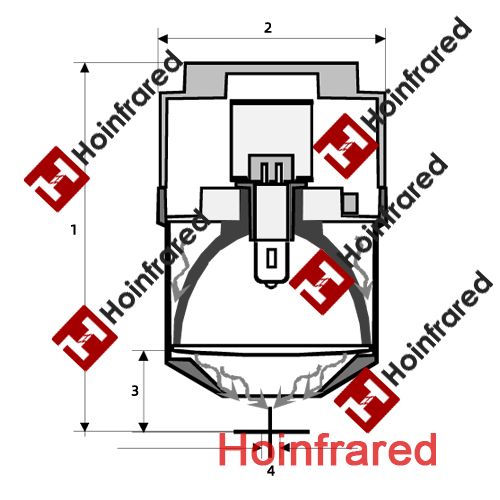

The light source is a 250 W halogen lamp, which emits light with wavelengths of 500-1500 nm. The lamp is surrounded by an ellipsoid reflector, which focuses the emitted light at the soldering point precisely where the heat is needed.

Infrared spot focusing heaters can efficiently focus infrared radiation energy on a specific small area, thereby generating extremely high heat flux density. The irradiation angle can be adjusted, the focal length can be adjusted, constant temperature setting is available, slope curve heating is possible, and open-loop power adjustment heating is feasible. This high-density infrared radiation can quickly and evenly heat the target material to a temperature above 1200℃, greatly improving heating efficiency and heating quality.

IR ray is a kind of electromagnetic wave. It transmits energy at the speed of light. The energy from the sun mostly transmits by it. In spectral distributions, ......

The revolutionary HS HeLeN lamps are based on HS'world-leading technology to meet the specific demands of zone heating and other applications that require l......

ApplicationHealth care & heating apparatusDrying equipmentBreeding farming industryMedical equipmentFry & baking equipmentBrewage & fermentation installationSte......