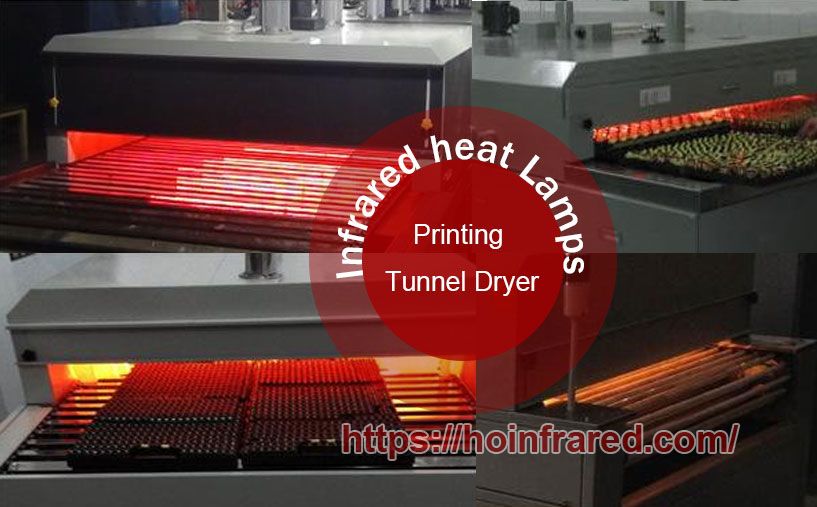

Commonly used in printing are environmentally friendly colored inks and water-based inks, so the water in the ink must be quickly evaporated during baking and drying, so as to achieve rapid drying and curing.

1. The radiation band of the carbon fiber infrared electric heating tube matches the absorption band of the object being dried

The OH-based vibration of water has a strong absorption band in the 2.7-3 micron and 6-12 micron bands, and the textile used for printing also shows a strong absorption band in the 2.5-15 micron band. Therefore, the drying section of the coating surface during the baking process of the printing dryer is heated by an infrared heating tube that is similar to the natural vibration frequency of water molecules, which can accelerate the volatilization of water and cosolvents. After the water absorbs infrared rays, the temperature rises rapidly and evaporates. , To speed up the surface drying of the coating. The infrared wavelength of the carbon fiber heating tube is 2.0-15um, which can match the absorption spectrum of water-soluble ink and water-based ink very well, as well as the absorption spectrum of textiles.

2. The infrared heat radiation efficiency is high, the drying time is shortened, and the color is high.

Carbon fiber electric heating tube is a kind of infrared radiation heat energy. Its energy transfer method is heat radiation. During the transfer process, the medium loss is very small. The infrared radiation energy is quickly absorbed by the substance's molecules without being blocked by the surface layer of the substance. The heating speed Fast and high. From the actual use effect, the use of infrared carbon fiber electric heating tube, using its simple and direct infrared radiation transmission method, the drying time of each color of the thermosetting ink is shortened to 2.5-5 seconds, and the drying time of the finished product is shortened to 30-60 seconds. . The production cycle is effectively shortened, and the power consumption is reduced by more than 30% compared with the traditional heating tube. It also effectively avoids foaming caused by the traditional heating method, and the internal moisture cannot leak after the surface is dried.

3. Infrared radiation heating is simple and easy to operate, clean and environmentally friendly, and stable electrical performance

Carbon fiber infrared electric heating tube is mainly used for high infrared heating technology, which is suitable for high output and high quality requirements of modern production technology. The power is stable during frequent startup, shutdown and long-term continuous work.

Graphene heat tubes have advantages such as high heat conversion efficiency, ultra-low power consumption, and high stability. Our Graphene heat pipes are prepa......

IR ray is a kind of electromagnetic wave. It transmits energy at the speed of light. The energy from the sun mostly transmits by it. In spectral distributions, ......