Many shoe factories that are already using infrared heating tubes for drying or activating shoe upper glues choose short wave IR lamps because the characteristics of SIR are fast response speed and high heating temperature. It feels that the required temperature can be reached in a short time, and the drying work can be completed, which can save time, that is, save energy.

There will be two problems:

1. The brightness is too bright, it is very dazzling every time you work, and the workers cannot check the working conditions;

2. The temperature is too high, the workers feel dangerous, and the high temperature is not easy to control, it is easy to overbake and cause damage and deterioration .

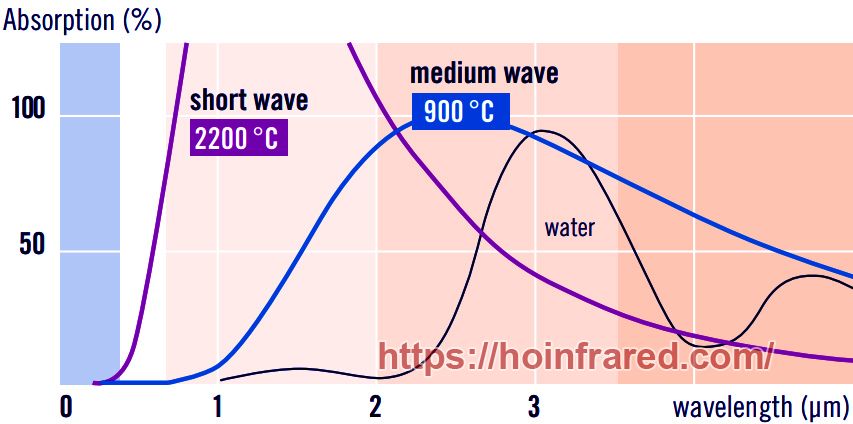

water evaporates more quickly with medium wave infrared emitters as water absorbs radiation particularly well in this region

In fact, in any drying process, the main heating target should be the moisture inside, not other solid resin substances, not the substrate or the workpiece. If the drying process, the heat provided can automatically absorb the heated material (moisture) to heat up the water as quickly as possible, while other materials that require less energy will absorb less energy. In this way, the drying process time is short, energy saving, equipment failure rate is low, workpiece temperature is low, and cooling time is short; the actual benefit to users is that the production speed is increased, and energy is greatly saved. With substantial savings in electricity bills and overall cost reduction, the profits that can be generated will rise sharply.

Drying or glue activation in the shoe industry is more suitable for medium-wave infrared heating tubes

Special Infrared Heating Lamp IR heating tube can be customized into a variety of different shapes to meet the requirements of different industrial environment......

Special Infrared Heating Lamp IR heating tube can be customized into a variety of different shapes to meet the requirements of different industrial environment......